About

Our Mission

Glass is inherently recyclable, as demonstrated by the container glass industry, where end-of-life glass is crushed and used to create new products. We aim to replicate this success in the architectural glazing sector, promoting a more circular economy that keeps recyclable materials out of landfills.

Our mission focuses on three key goals:

- Educate: We aim to demonstrate how architectural glass can be efficiently removed from buildings, sorted, and processed to maximise its recyclability at the end of its life. We believe that with the right knowledge, recycling architectural glass is straightforward and effective.

- Connect: We strive to bring together key players - processors, recyclers, and installers – to form a network of businesses engaged in the recovery and recycling of architectural glazing.

- Impact: By achieving the first two goals, we hope to increase the rates of recovery and recycling of architectural glazing. This, in turn, will help lower the embodied carbon in future glass products and improve resource efficiency.

Together, these three aims guide our efforts to ensure that glass, as an inherently recyclable material, is integrated into a more circular economy.

Glass Industry Energy Consumption

The glass industry is one of the UK's eight energy-intensive industries. It accounts for betweenEstimation of Available Tonnage in Buildings

Our estimated is thatTotal emissions savings if use available tonnage

If all of the 700,000 Tonnes of glass were recycled and used in new flat glass production:Benefits of Glass Recycling

Recycling glass offers significant environmental benefits, which is crucial in addressing the climate crisis. By using more recycled material, known as cullet, in the production of flat glass, the volume of raw materials, which otherwise would have been extracted for use, is reduced.

Cullet has already undergone the steps involved in glass production. Since it's been melted once before, and the carbon emissions associated with that process have already been released, the introduction of cullet into flat glass feedstock results in lower carbon emissions compared to using raw materials. Additionally, the energy needed to melt cullet is less than that required for raw materials, therefore reducing energy consumption.

For businesses, recycling glass can also be a cost-saving measure. Glass installers and processors often pay to dispose of waste like old glazing units. By partnering with recyclers instead of sending these units to landfills, businesses can significantly cut waste disposal costs while contributing to a circular economy. Increasing profitability with minimal interruption to the business operation.

As glass recycling continues to grow, it also creates opportunities for business expansion and innovation. This evolving industry will facilitate the development of new skills, allowing businesses to meet the increasing demand for recycling expertise and solutions in future.

Supply Chain

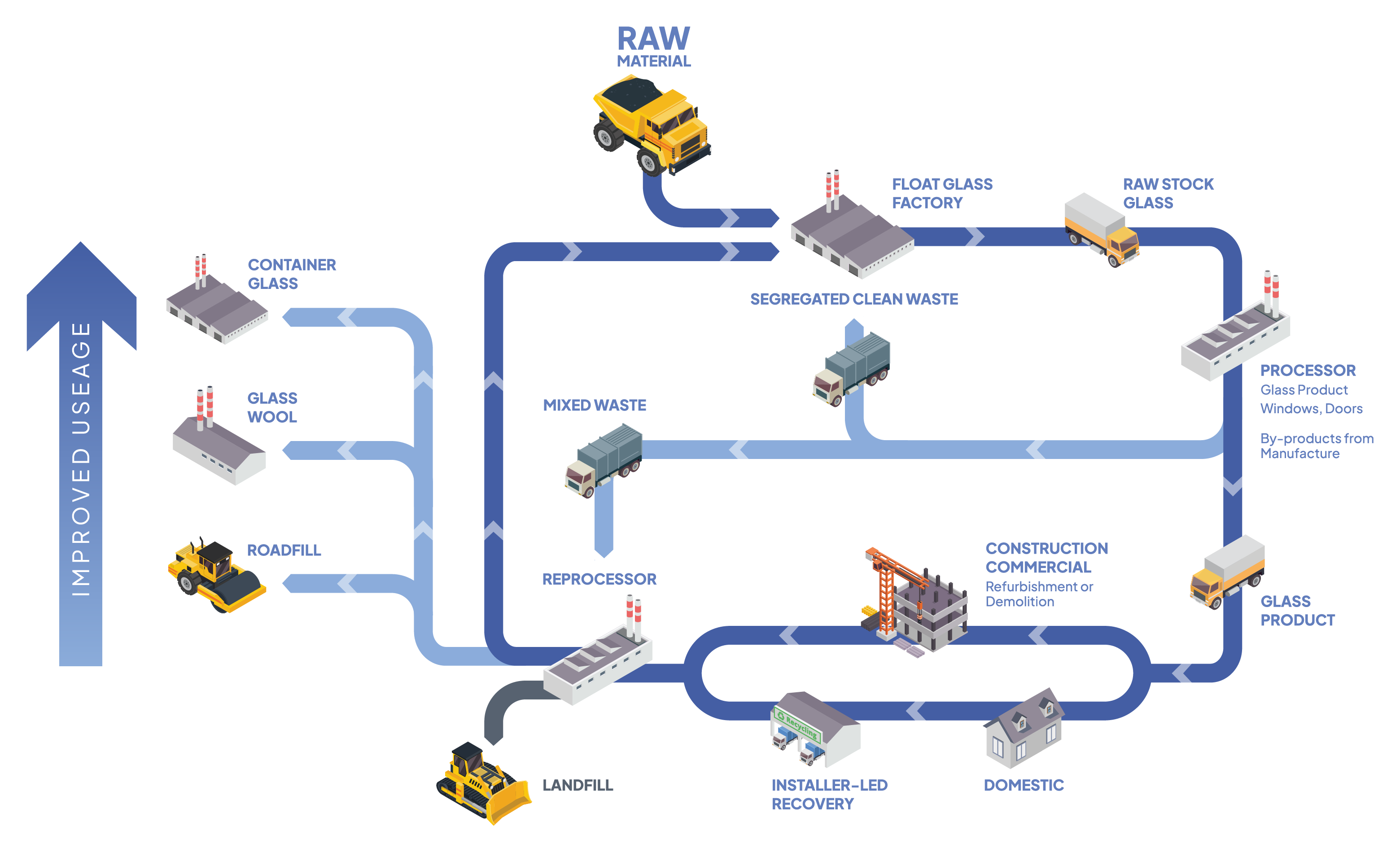

The production, transport, installation, and disassembly of glass in buildings involves a range of players in the supply chain. Currently, these parties often operate in isolation. Given that the lifespan of architectural glazing can be 20 to 30 years or more, there is a disconnect between some of the key players. Moreover, the flat glass recycling sector is still in its early stages, and the necessary links between installers and recyclers are not fully established.

The diagram below represents the scenario we're working toward. In this model, all parties are connected within a glass recovery and recycling network.

By improving connections between the various players in the flat glass supply chain, it will become gradually easier and more efficient to recover and reuse architectural glazing materials.

Ideal Scenario

- Glass Producers - float lines where architectural glass is produced.

- Installers - both for small and large scale projects, installers fit windows, curtain walls and other glazing systems. They also are involved in replacement and refurbishment of old glass units.

- Re-processors and Recyclers - companies who accept pre and post-consumer cullet, carry out sorting and grading of material and pass on to relevant parties for recycling or re-use.

- Haulage Companies - critical for the transport of glass products and waste at small and large scales.

The integrated approach, where key parties are linked, will maximize the amount of glass material that is reintroduced into the flat glass production process, reducing waste and supporting a more circular economy. This will also help reduce costs to businesses associated with disposal of material, with glass units at end of life being passed to recyclers rather than landfill.

There are a variety of glass types used for architectural applications. The type of glass has an impact on its ability to be recycled. Clear, unlaminated glass is the most straightforward to recycle. However, other types of glazing can be recycled with additional effort. Some types of glazing, such as fritted glass, cannot be used in the production of new architectural glazing products due to the ceramic material used in the frit. However, there are still opportunities to downcycle this type of material rather than send directly to landfill. Please see our "How it Works" section for more information.